Ion trap demonstration experiments completed.

It has been a while since I posted anything, mostly because I have done nothing other than work on some demonstration experiments for my old phd supervisor. These are now finally finished so here we are.

First a little background. I was asked before Christmas to build 2 demonstration experiments to show undergrads, prospective students and interested members of the public the fundemental principles of trapping single charged atoms, or ions. The first of these experiments is a mechanical analogy, a saddle shaped peice of wood/plastic/something representing the electric field. In one direction it will trap the ball, since it can’t roll up a hill. However, in the other direct it will happily roll down the side. To prevent the ball rolling off the saddle it is rotated, and when the rotation speed is just right the ball will oscillate back and forth inside the saddle, effectively trapping the ball. This is exactly the same principle as how atomic ions are trapped inside an ion trap, except swap the wooden saddle for an electric field. The second experiment is just to build an ion trap but to trap dust particles. An ion trap is a very simple device, it consists of 4 electrodes, which are four parallel rodes each on the corner of a square. Then two more acting as end caps. This arrangment of wires can be used to trap charged particles ranging in size from specks of flour to signal atomic ions. To trap big heavy particles of flour we need a lot of voltage, about 6000v should do it and oscillating at tens of Hz… 50Hz is convenient.

So as far as building these devices they offered two different problems each, the saddle trap was a) how to make a saddle b) how to rotate the saddle. For the dust trap a) how to generate such a large voltage and b) how not to kill anyone.

Saddle trap:

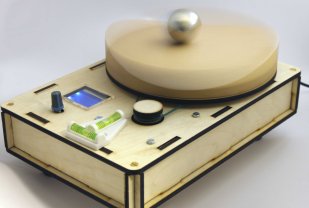

To address the first issue of how to build a saddle I had two options additive or subtractive fabrication. I quickly ruled out the 3D printer due to the poor surface finish and opted on a piece of kit I have never used before, a model mill. I managed to get trained up and after test with foam I managed to mill out a beautiful wooden saddle. It took about 2.5 hours but the results were lovely and required only minimal sanding. See this video for a time lapse of the milling. For protection from all those grotty little fingers I just gave it a couple of coats of tung oil, giving it a nice wet look finish. The saddle completed I dug through the trove, a room full of “junk” at the hackspace, this stuff has all been kindly donated and if it hasn’t got a stick you can use it. In amungst all the stuff is a couple of large boxes full of fans. Mostly PC fans but all sorts. Out of here I found a 12v PC fan and a 240v mains fan. The mains fan being designed to run from AC has a lovely smooth bearing and will rotate freely, none of the magnetic steps in DC fans. This would act as my bearing to hold the saddle. To drive the saddle the 12v fan would drive a spindle and a belt would connect the two. To control the speed of the saddle the current to the fan would be controller by the PWM output from an Arduino, this would also show the target speed on a little Nokia LCD. Nice. Now just put the whole thing in a laser cut box and we’re in business. (There were a few more trial and error stages that the author may or may not have omitted.) In the end I was asked to build two, this time with a larger saddle. Fine except for a 4.5 hour mill time! However the results have been awesome and I’m gonna have to build myself one! Here’s a video of the large saddle in operation.

A rotating wooden saddle is capable of trapping a ball in centre, preventing it from falling off.

Dust trap.

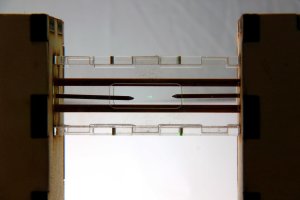

For the dust trap my main concern was safety. If this is to go near the general public it can’t kill anyone! After playing with lots of different transformers and audio amps I borrowed a microwave amp and I was in business. These have the benefit of being built for purpose. They are designed to generate the voltage I need. However, they also will kill you just if you look at them wrong. My solution, current limiting resistors. Lots of them. Since all I am interested in to trap dust is voltage then the current can be arbitrarily low. The trap itself acts as a very small capacitor, the impedance of this capacitor at 50Hz is huge so placing 10Mohm in series before the trap makes virtually no difference to the trap voltage, it does mean though, should a stupid finger get between the electrodes so little current can be drawn no one will die. Also encasing the electrodes in plastic helps. This works great for trapping dust, flour, cumin and best of all baking powder. Though strangely mustard power doesn’t trap. Here’s some pics and a video.