I needed to make a data logger to measure the inductance of a coil over time. The coil is flexible and so will distort while in operation. I wanted to know how much this would change the inductance in order to account for it.

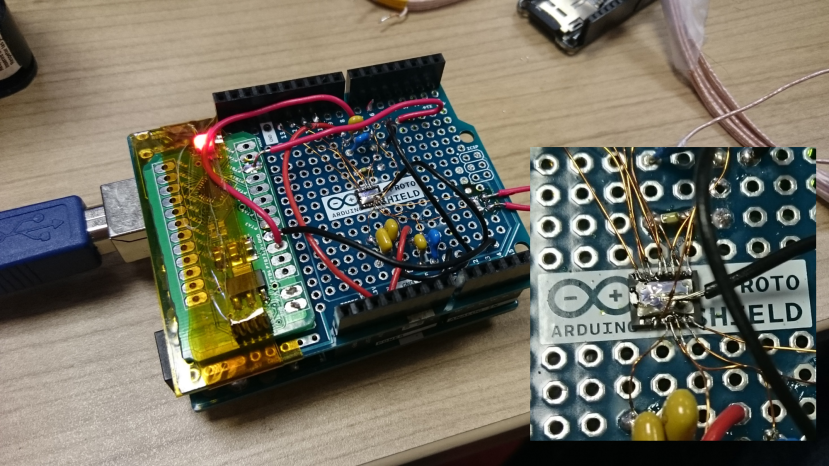

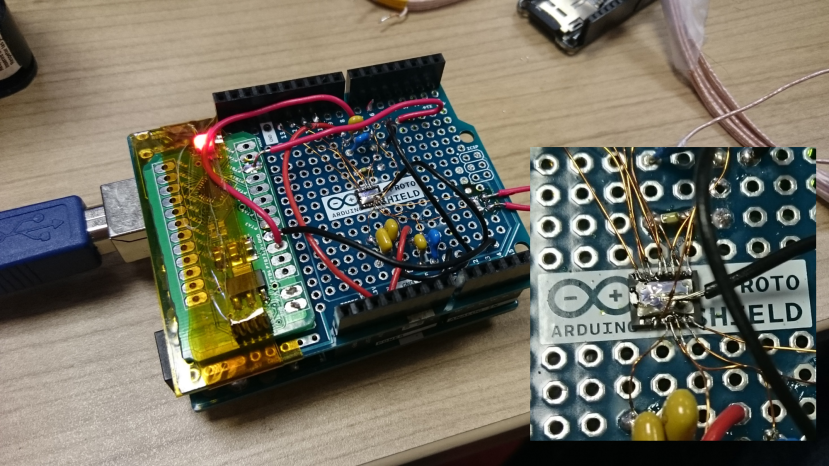

I found a nice IC from Texus Instruments, the LDC1000 inductance to digital converter. However it comes in an annoying SON-16 package, so time to whip out the fine tip soldering iron and practice my dead bug wiring. (For various reasons I thought logical at the time (though probably not) I opted not to use the handy eval board.)

So I superglued it onto an arduino protoshield, added a few caps and it was done. To measure the inductance the LDC1000 needs to be clocked, which is what the green board kapton taped to it is doing. This is a breakout I made for the Freescale/NXP KL03 cortex M0+, clocking the LDC1000 at 3MHz. You might ask why am I using the arduino for the logging and the KL03 to clock. Well. Whatever.

I plugged in an Adafruit datalogging shield and a few simple lines of code later I was logging inductance data. Sweet.